Reverse printing & lamination for Flexible Packaging.

Lamination to paper & board.

Labels & Hot Foil Stamping.

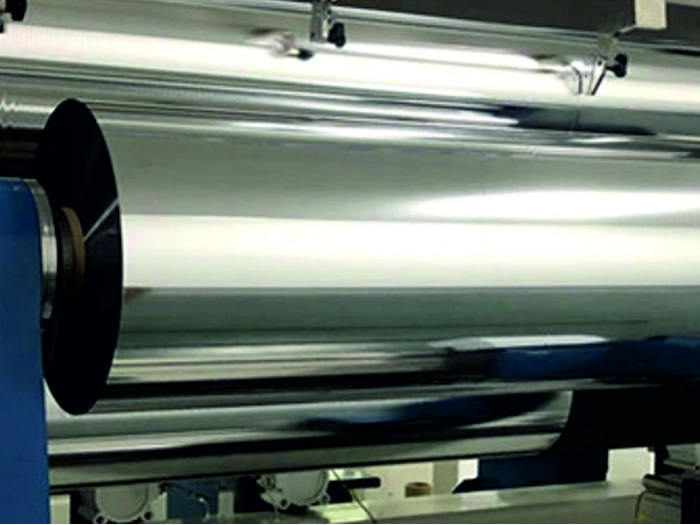

Metallizing for flexible packaging, micro slitting & yarn

Electrical Insulation.

Release Film

Transparent, high gloss & excellent clarity, Corona treated on either side with Slip Er anti-static properties for good machine ability & printability for flexible packaging.

Corona treated side is specifically designed for excellent adhesion of inks & adhesives.

| PROPERTIES | TEST METHOD | UNIT | TYPICAL VALUES | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | Internal Internal |

(μ) Gauge |

8 32 |

10 40 |

12 48 |

15 60 |

19 76 |

23 92 |

36 144 |

||

| Yield | Internal Internal |

m2/kg n2/Ib |

90 63300 |

72 50600 |

59.52 41934 |

47.62 33550 |

37.59 26483 |

31.05 21876 |

19.84 13978 |

||

| Surface Tension (min) # (Corona Treated Surface) | ASTM D - 2578 | dyne/cm | 48 | - | - | - | - | - | - | ||

| COF (max) (Corona Treated to Untreated (Untreated to Untreated) | ASTM D - 1894 | - | 0.5 0.45 |

0.5 0.45 |

0.5 0.45 |

0.5 0.45 |

0.5 0.4 |

0.5 0.4 |

0.5 0.4 |

||

| HAZE | ASTM D- 1003 | % | 3.5 | 3.5 | 4 | 4 | 4 | 4.5 | 5 | ||

|

ASTM D 882 | kgs/cm2 | 2000 2100 |

2000 2100 |

1900 2000 |

1900 2000 |

1900 2000 |

1900 2000 |

1750 2000 |

||

|

ASTM D 882 | % | 110 100 |

110 100 |

105 85 |

105 85 |

110 85 |

115 90 |

120 90 |

||

|

ASTM D - 1204 | % | - - |

- - |

5 0.6 |

5 0.6 |

5 0.6 |

5 0.6 |

- - |

||

|

3.5 0.5 |

3.5 0.5 |

3.5 0.5 |

3.5 0.5 |

3.5 0.5 |

3.5 0.5 |

2.5 0.8 |

||||

|

ASTM F - 1249 | gm/M2/daygm/100in2/day | 60 3.8 |

40 2.5 |

45 2.9 |

40 2.6 |

35 2.3 |

30 2 |

20 1.3 |

||

|

ASTM D - 3985 | cc/m2/daycc/100in2/day | 140 8.8 |

130 8.1 |

130 8.5 |

110 7.1 |

90 5.8 |

80 5.2 |

70 45 |

1) Above properties can be modified to suit customer's requirement.

2) Unless otherwise specified, the values given above are nominal.