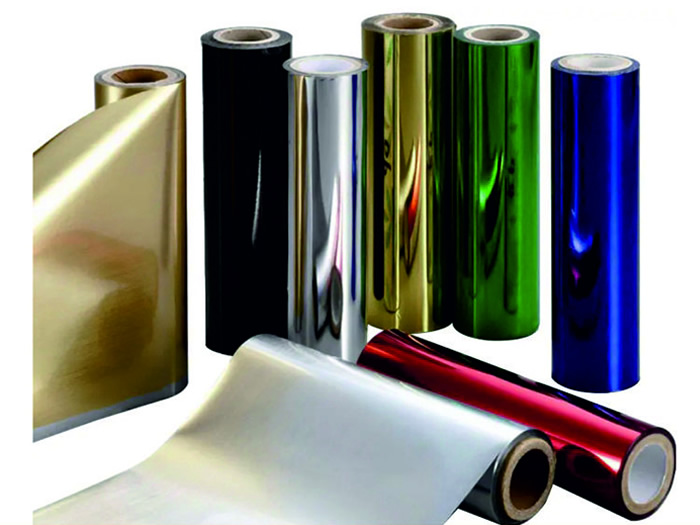

Lamination for flexible packaging.

Micro slitting for yarn.

Sequins & glitter.

Gift wraps.

Paper plates.

One side Metallised for lamination & flexible packaging. Plasma treated for High metal bond strength & barrier properties.

| PROPERTIES | UNIT | TEST METHOD | TYPICAL VALUES | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 9 | 10 | 12 | 15 | 19 | 23 | |||||

| Optical Density *** (Tolerance: +/- 5%) (***Customer to specify the 0.D. value as per their application) |

SD HD VHD |

2.2 - Normal Packaging Application 2.5 - High Barrier Application 2.8 - Special Application |

||||||||

| Thickness Average Gauge |

(μ) (Gauge) |

Internal |

9 36 |

10 40 |

12 48 |

15 60 |

19 76 |

23 92 |

||

| Film Density | gm/cc | D -1505 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | ||

| Grammage | gm/cc | Internal | 12.6 | 14 | 16.8 | 21 | 26.6 | 32.2 | ||

| Yield | g/m2 | Internal | 79.36 | 71.42 | 59.52 | 47.62 | 37.59 | 31.05 | ||

| C.O.F(Tr.Film/Un tr.Film) | Static/Kinetic | ASTM D-1894 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | ||

|

kgs/cm2 | ASTM D 882 | 1900 2000 |

1900 2000 |

1900 2000 |

1900 2000 |

1900 2000 |

1900 2000 |

||

|

% | ASTM D 882 | 90 80 |

100 80 |

105 85 |

105 85 |

110 85 |

115 95 |

||

| MVTR (38°C & 90% RH) | gm/m2/day | ASTM D - 1249 | SD 1 |

HD 0.6 |

SD 0.4 |

|||||

| OTR (23°C & 0% RH) typical |

cc/m2/day | ASTM D - 3985 | 1.1 | 1 | 0.8 | |||||

The film have superior gloss when metalized on optically clear base film and further improved when metallized on extra clear base film. Film is available in optical density ranging from 1.4 to 3.0. The wide range of optical densities give choice to the customer to use the product for diverse range of applications. The metallization is available on plain side (MU) or on corona treated side (MT), as specified by the customer. The bond between the metal and film is 100-150gm/25mm (when metallized on plain side) & 130-180gms/25mm (when metallized on corona side).